Timeless Horological Techniques

Our vision revolves around the creation of timeless timepieces that preserve the classical techniques of watchmaking used over two centuries ago. This is accompanied by a commitment to embracing modern designs while showcasing expert craftsmanship.

We aspire for your timepiece to become an elegant reminder of an ancient tradition, embodying a durability as immutable as time itself.

Each creation we conceive is imbued with this vision, offering a harmonious alliance between

the past and the present.

Thus, your watch becomes much more than a mere timekeeping instrument; it becomes a timeless horological piece, a witness to a rich and eternal history.

Guilloché

The Art of Finishing

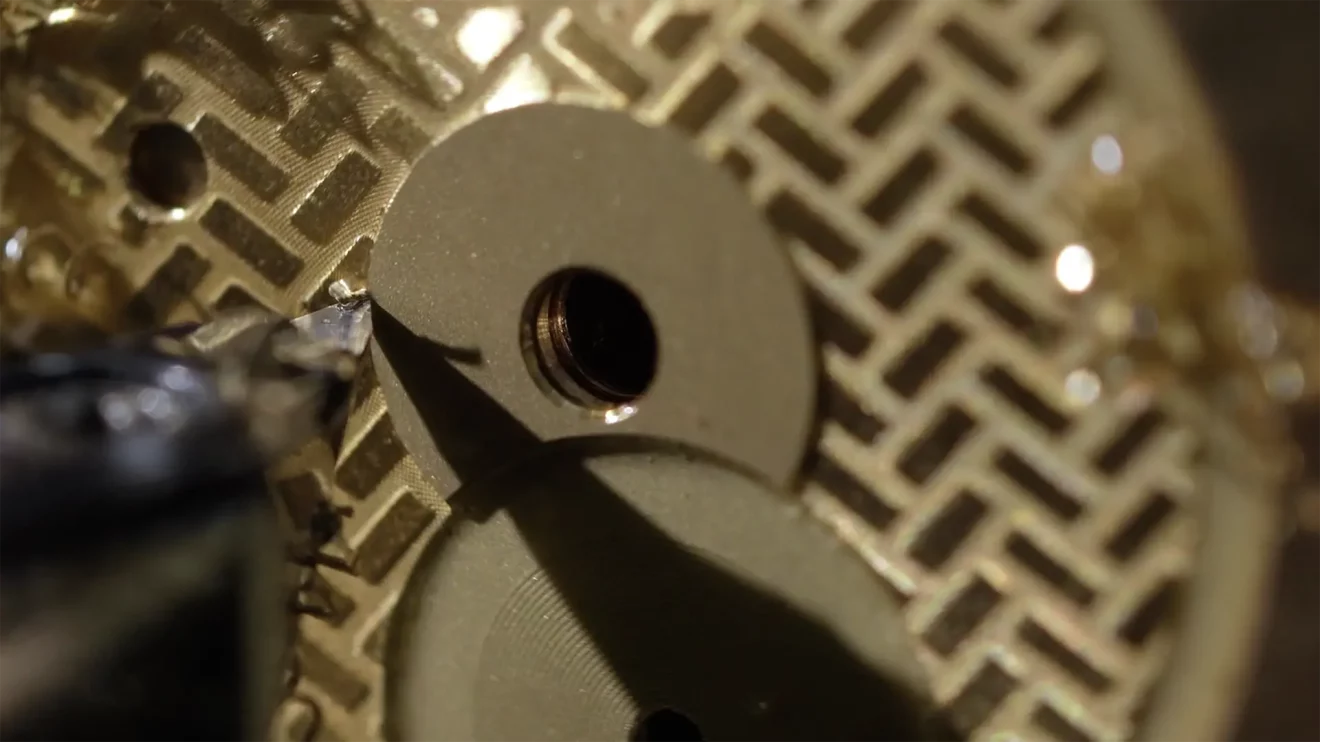

Guilloché is a decorative engraving technique that demands exceptional precision and unparalleled artisanal expertise. By engraving intricate and repetitive patterns onto metallic surfaces, often using guilloché lathes or straight-line machines, the artisan creates unique effects of light and texture, transforming each piece into a work of art. The patterns, which can include waves, spirals, or geometric shapes, enhance the depth and beauty of the timepiece, bringing its details to life with every glance.

Guilloché of the SYNC1863

The dial of the CG SYNC-1863 is enhanced by artisanal guilloché, executed on semi-automatic machines dating from the 1960s. This traditional guilloché, in the ‘Ancienne Tapisserie Guillochée’ style, creates complex and repetitive patterns inspired by historic fabrics and tapestries, adding depth and texture to the dial. This traditional method demands great precision and artisanal expertise, endowing the dial with unique depth and texture. The guilloché of the SYNC-1863 embodies the perfect balance between heritage and innovation, paying tribute to traditional watchmaking artistry while integrating modern techniques to deliver incomparable elegance.

Enamelling

The pinnacle of watchmaking craftsmanship!

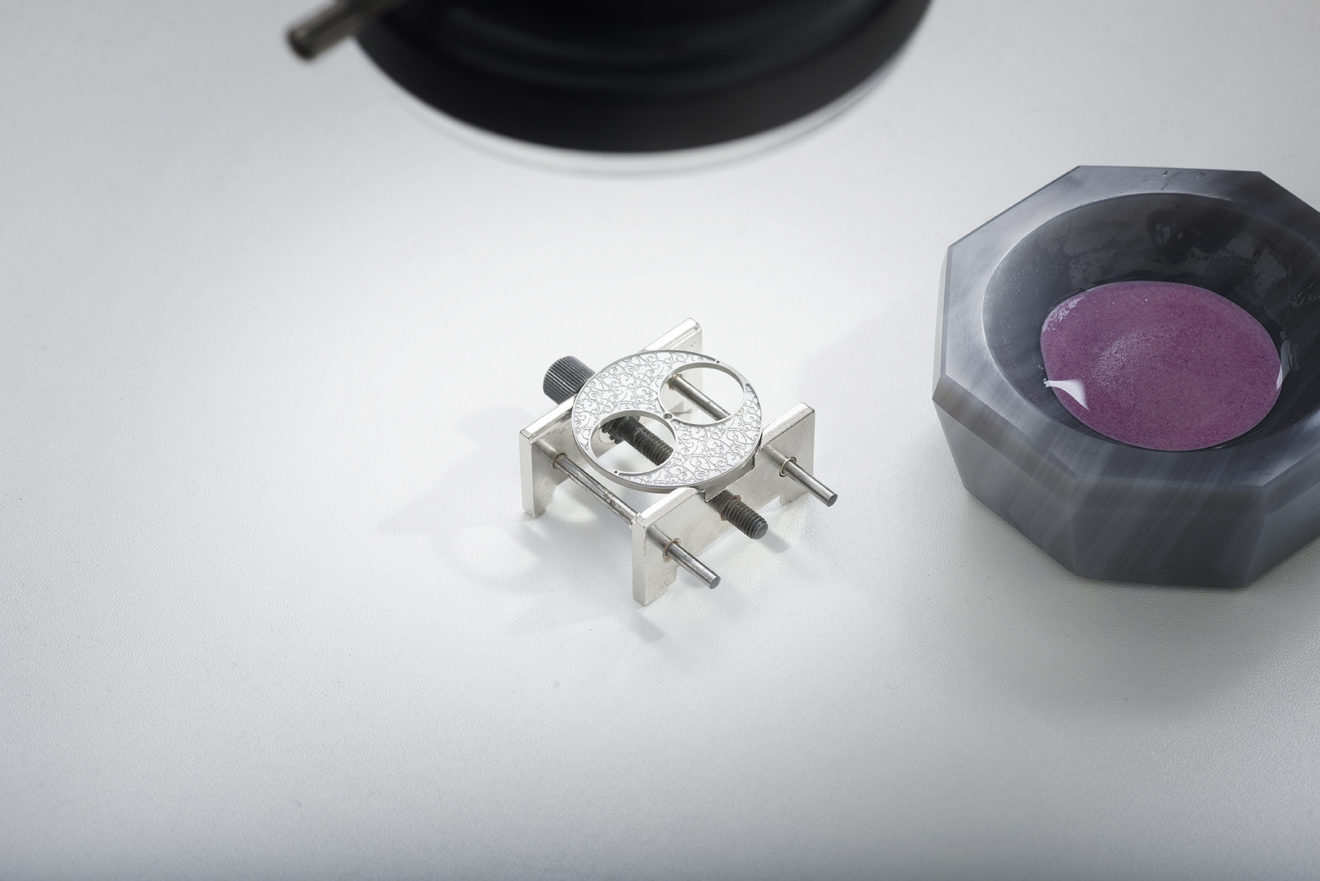

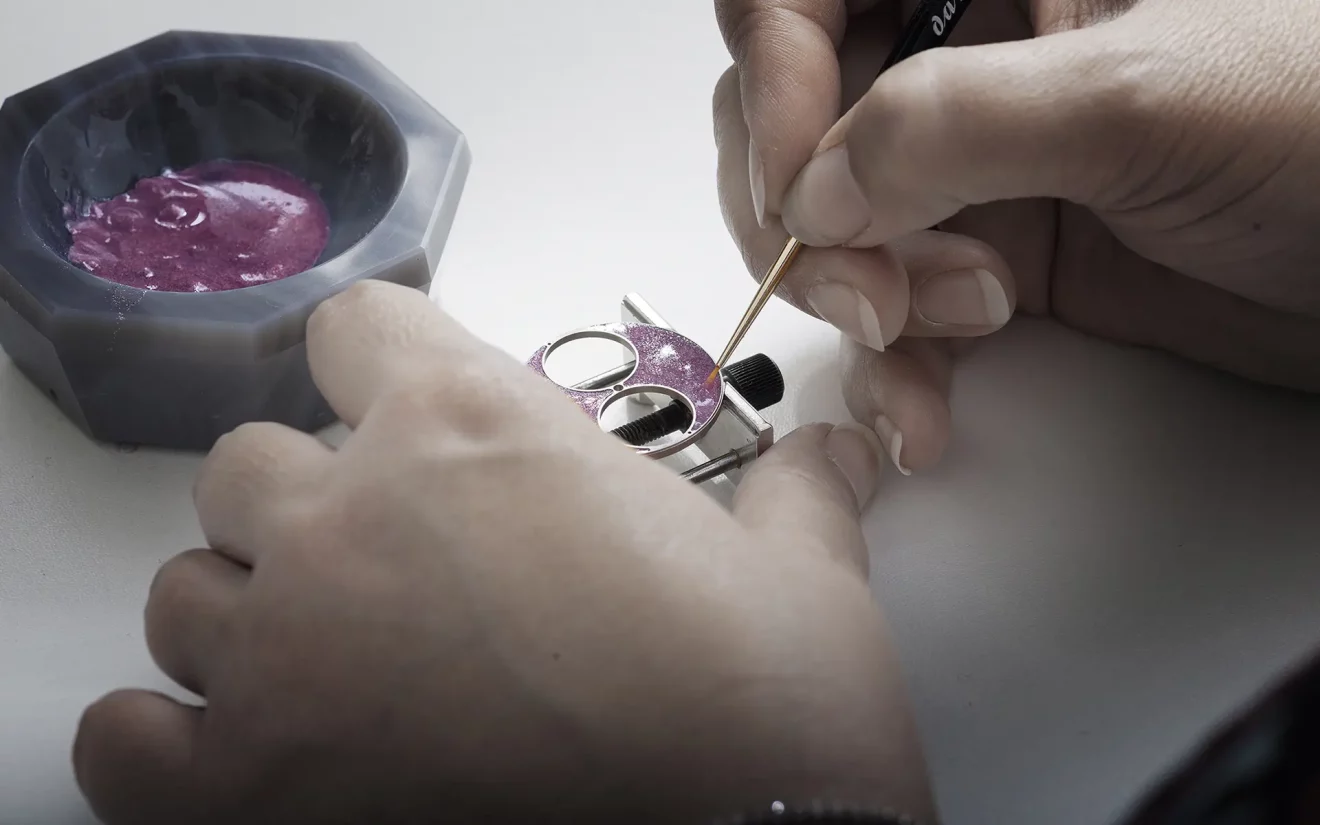

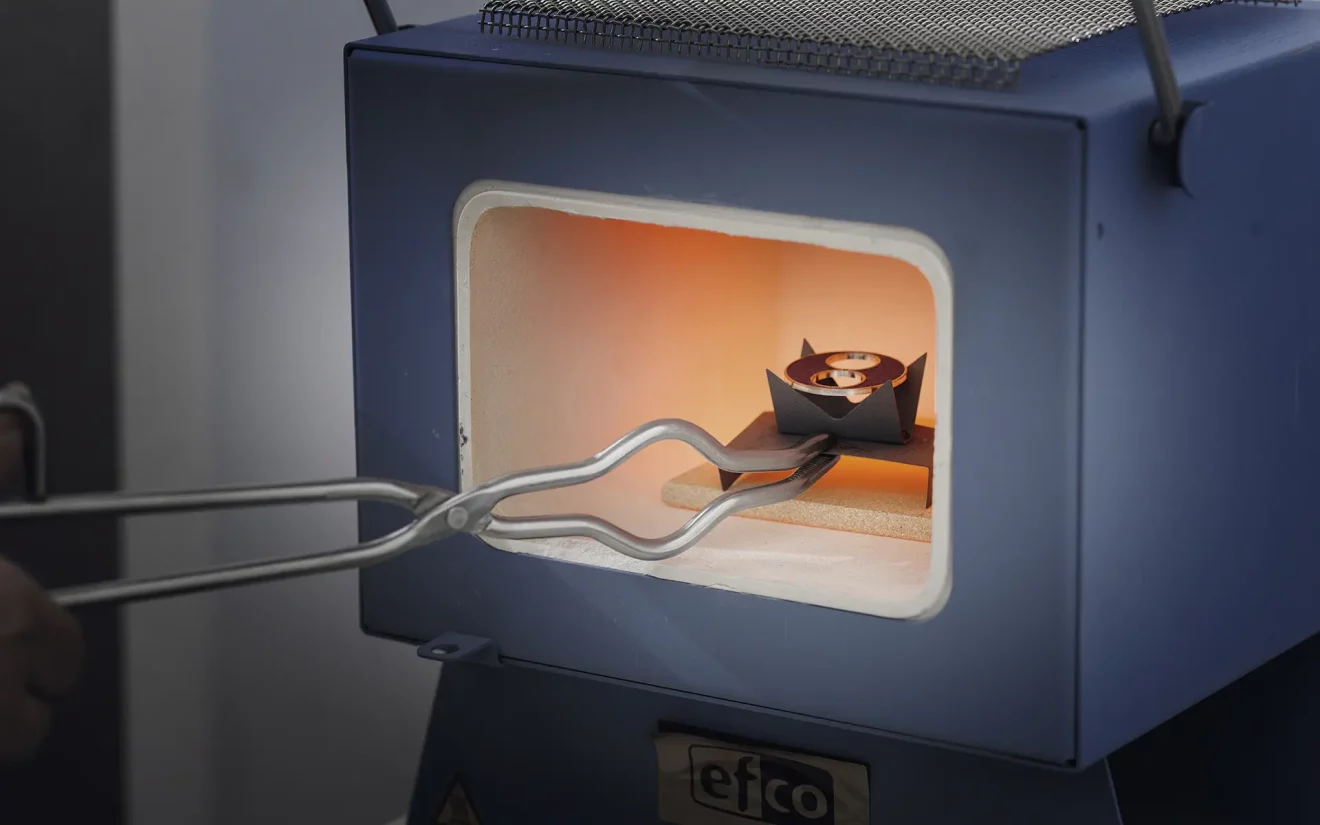

The delicate art of enamelling, often practiced by prestigious manufactures, represents the pinnacle of watchmaking craftsmanship. This demanding process involves the meticulous fusion of glass powder at extremely high temperatures, a true challenge for artisans. At Charles Girardier, this complex technique is used to adorn our dials, creating pieces with vibrant and enduring designs.

Every step of the process, from the careful preparation of coloured glass powder to the delicate application on a prepared metal surface, requires exceptional expertise and craftsmanship. Repeated firing at high temperatures results in an ultra-resistant surface fused with the metal base.

Enamel artisans, true artists, are also alchemists and visionaries. They anticipate the complex interactions between pigments, ensure colour stability, and envision the final nuances.

Various ancestral techniques, such as cloisonné, champlevé, paillonné, and miniature painting on enamel, are implemented with precision to create pieces of dazzling and timeless beauty. Enamelling thus becomes a dialogue between tradition and innovation, embodying the quintessence of high-end watchmaking craftsmanship.

Fine Enamelling Techniques

The fine nuances of the art of enamelling are revealed through five distinct techniques, each executed with precision by rare master enamellers who command their subtlety.

In the cloisonné technique, a delicate gold wire—often less than 0.5 mm in diameter—is skillfully bent and shaped to outline forms on a plate previously coated with a thin layer of enamel. After an initial firing, the defined shapes are filled with various enamels, sometimes requiring several firings to achieve the desired nuances, transparencies, and depth.

The champlevé method, similar to the previous technique, involves depositing enamel into cavities, with the plate having been previously engraved. Ce processus, parfois mécanique pour des motifs simples, devient un travail manuel complexe pour les pièces uniques. L’émailleur comble les espaces préalablement gravés à la main, ajoutant une palette de nuances et de couleurs.

The paillonné technique, on the other hand, showcases tiny leaves of gold or silver cut into intricate patterns, called paillons, integrated into layers of transparent enamel.

Miniature enamel painting, the rarest of these techniques, stands apart for its unique approach. From the outset, the enamel is handled differently, mixed with oil rather than water. Delicately applied with a fine brush onto an initial layer of enamel, this method allows for the miniature reproduction of pictorial masterpieces, expressive portraits, vivid landscapes, or complex scenes.

The camaïeu enamelling technique is a refined artistic method that involves using subtle shades of a single enamel colour to create a monochromatic gradient effect. This delicate approach emphasizes the richness of tones in a single colour, ranging from light to dark, to produce a subtle and nuanced palette.

In this technique, the enamel artist works with a limited palette of colours from the same family, creating visual harmony through a gentle gradation. Each shade is precisely applied to the prepared metal surface, then fired at high temperatures to fuse with the base. This process is repeated several times, allowing the artist to play with variations in tones and create captivating visual effects.

Camaïeu enamelling requires meticulous expertise to achieve a perfect balance between shades and to ensure a smooth transition from one tone to another. The final result is an enamelled work of art of timeless elegance, where mastery of colour and the subtlety of gradation combine to create a unique and refined piece.

Bevelling

Manual finishing

Bevelling is one of the most demanding finishes in fine watchmaking. Made entirely by hand, it consists of chamfering and polishing the edges of the movement’s components to create a perfectly even, luminous bevel.

At Charles Girardier, every angle is worked with extreme care, revealing the geometry of bridges and the depth of volumes. This exercise in mastery, invisible to the layman but essential to the discerning eye, testifies to the time devoted to each movement and to our commitment to watchmaking truth, where finishing is a signature.

Moulding

Manual finishing

The moulding of the screw holes is a high-precision watchmaking finish. It consists of gently shaping and polishing the perimeter of each housing to create an even, perfectly clean curve around the screw head.

Carried out by hand, this operation ensures impeccable support for the screw, while adding a discreet elegance to the movement. At Charles Girardier, the moulding contributes to the visual harmony of the bridges and bears witness to the care taken in even the most minute details, where the demands of fine watchmaking are fully expressed.

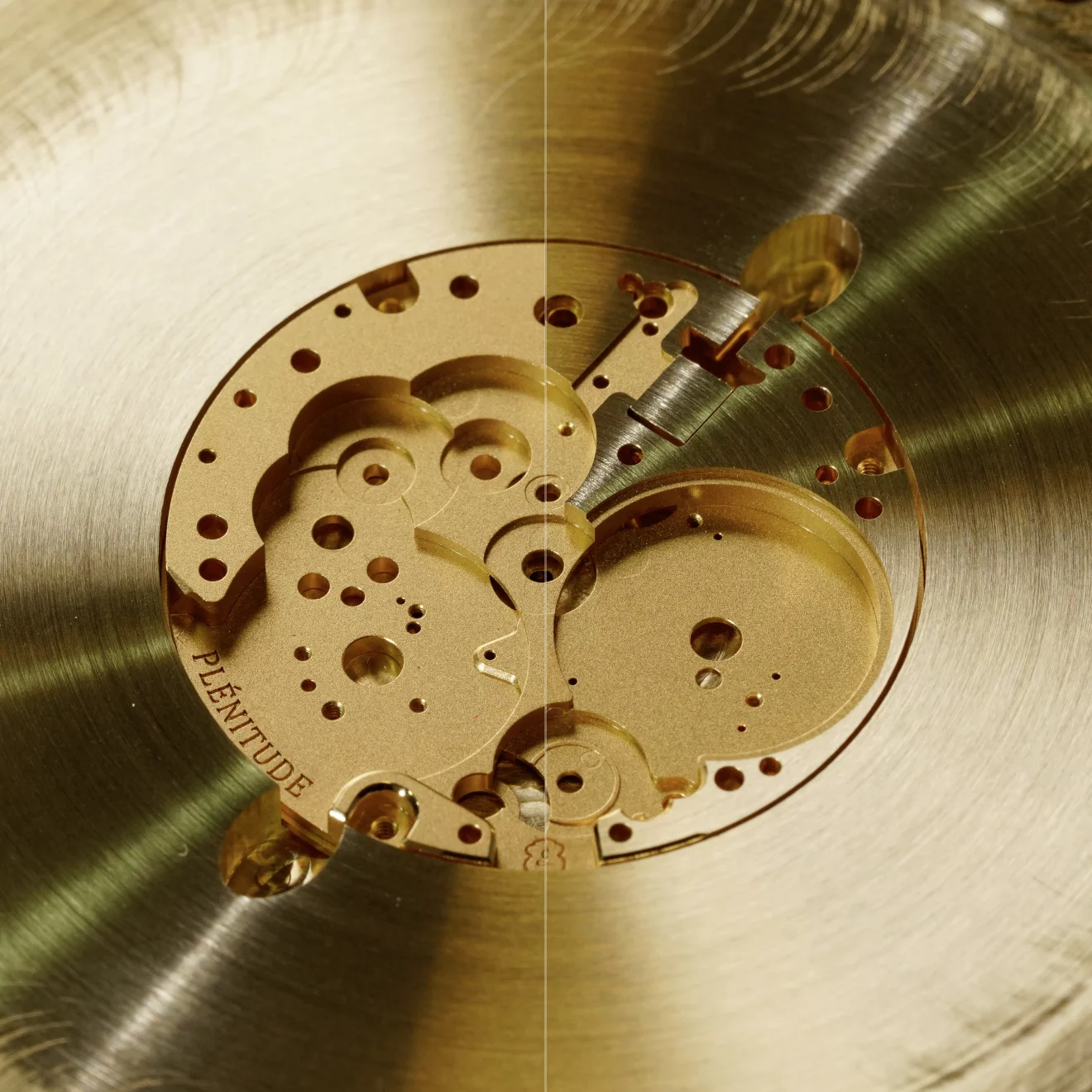

Circular satin finishing (platinum)

Manual finishing

Circular satin-finishing of the plate is a traditional finishing technique that consists of applying a regular pattern of fine concentric striations to the base surface of the movement. Performed with perfect mastery of the gesture, it demands consistency, precision and a sense of rhythm.

At Charles Girardier, this decor visually structures the movement, subtly capturing the light and highlighting the hand-finishing that accompanies it. An unobtrusive but fundamental support, the satin-brushed plate becomes the base on which the rigor and balance of watchmaking construction are expressed.

Cabronage

Manual finishing

Cabronage is a manual surface finish, comparable to anglage in its gesture requirements, but applied to flat surfaces using extremely fine abrasives. This operation evens out the material, unifies the grain and produces a perfectly controlled matte surface.

At Charles Girardier, cabronage is used to complete certain parts of the movement, when legibility of form and visual coherence are paramount. Discreet and demanding, it bears witness to a finishing process in which the hand guides the material, right down to its quietest details.